As we move towards cutting-edge technological advancement, manufacturing is maturing to offer us more robust results. The trend of automation is becoming mainstream, and the industrial world is among the early adapters. In addition, the concept of Industry 4.0 is paving a new way of manufacturing across multiple domains

In simple terms, when manufacturers leverage digital and robotic techniques to improve their production process, it’s called Industry 4.0. Some key technologies used in this advancement are wireless networking, cloud integration, and 3D technology. Furthermore, as additive manufacturing is also becoming mainstream among industries, it will help drive the industry 4.0 revolution.

What is 3D Printing?

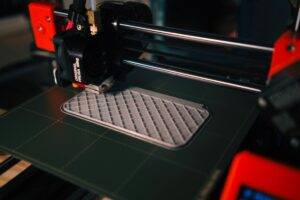

3D printing or additive manufacturing is making three-dimensional solid objects from a digital file. 3D printers generally use different materials like plastic, metal, ceramic, wood and even food to create products. The printer builds the product by laying down successive layers of material until the object appears. There are several 3d printing technologies available in the market. Let’s take a quick look at them:

Fused Deposition Modeling (FDM) is one of the most commonly used 3d printing processes, which creates an object by heating and extruding plastic material. The other technologies are Stereo lithography (SLA), Digital Light Processing (DLP), Selective Laser Sintering (SLS), Electron Beam Melting (EBM).

3D printers working on Fused Deposition Modeling technology are becoming cheaper day by day due to their high demand. In addition, as 3d printing technology drives more flexibility and agility and automation into the manufacturing process, it becomes an ideal choice for Industry 4.0 implementation.

Is 3d Printing a Right Fit for Industry 4.0?

As additive manufacturing is disrupting mainstream industries, it can also drive the industry 4.0 revolution seamlessly. For example, 3D technologies are already being used in the aerospace & automotive industry. Designers integrate digital product models with components to run quick design-to-market iterations to meet consumer demand.

It’s not just about large industries, though; even small-scale manufacturers see its true potential and adapt their processes accordingly. The same trend is expected for other domains, eventually pushing us towards the fourth industrial revolution.

Industry 4.0, along with 3d printing, helps businesses tackle challenges like reducing cycle times, minimizing costs without compromising quality, achieving mass customization etc., thus paving a new path across multiple business verticals. It will bring about a drastic change in designing, manufacturing, distributing, and consuming goods & services. 3D printing in Industry 4.0 will act as a catalyst in this evolution.

Industry 4.0 will be an interconnected and intelligent system that will drive incremental growth for all the stakeholders involved. It would open new avenues of business opportunities, and 3d printing will play a significant role.

The Advantages Of 3D Printing in Industry 4.0

Apart from applications like rapid prototyping, 3D printing can bring several advantages under the industry 4.0 revolution. It can work seamlessly with other conventional technologies like CNC machining and vacuum casting. Some of the key benefits are:

Increased Efficiency

3D printing can drive efficiency in several ways. For example, it dramatically reduces the time required to develop a product prototype by eliminating the need for tooling. Efficiency is a critical factor in Industry 4.0, and companies can leverage 3D printing to build efficiency in several other areas. The scope of 3d printing applications is not limited to prototyping; it is used for education, marketing, or decision making.

Adaptability & Customization

Beyond prototyping, manufacturers are also leveraging additive manufacturing to empower their production processes by customizing products according to consumer needs. It is touted that Industry 4.0, along with 3d printing, will bring more customization options for consumers. It will lead towards mass personalization of goods & services provided across multiple domains.

Mass Production at Lower Cost

The additive manufacturing process offers high-speed production without compromising on quality. This quality makes it favorable over traditional manufacturing technologies. As a result, it will drive down overall costs while keeping products of superior standards within reach of everyone.

Mass Customization

IT implies that several items from a production run can be manufactured with different specifications or at a low cost. For instance, car manufacturers print grilles according to vehicle make & model. Thus, mass customization is a crucial aspect of Industry 4.0.

3D printing offers greater precision over traditional processes, which help in trained professionals’ reliable monitoring of industrial equipment. It is possible to perform anywhere at any time without having to be physically present there. It will significantly reduce the downtime required for servicing industrial machines, thus increasing their overall productivity and efficiency exponentially.

Integrated Supply Chain Management

This technology now makes it possible for manufacturers to design, store and deliver 3D printed parts digitally. It further reduces the time taken to process orders and ensures faster delivery of products. As a result, 3d printing is helping usher an integrated supply chain management across multiple business verticals, and it’s a dire need for Industry 4.0.

3D Printing Industrial Applications

3D printing services offer a variety of applications that accelerate Industry 4.0 implementation. Some of the vital industrial applications are:

Rapid Prototyping

This technique is widely used across industries where prototypes of products need to be developed as soon as possible. It allows product designers and manufacturers to test various concepts and view their performance under real-life conditions before full-scale manufacturing. The ultimate goal is to bring down the time taken for developing a prototype and thus significantly reduce the total cost involved in product development.

Direct Digital Manufacturing

This new approach over traditional mass production aims to offer customized products explicitly tailored to individual requirements or preferences without incurring high costs for tooling & set up. For example, with direct digital manufacturing, companies can use swarms of small 3D printers working together on a part to produce a more significant number of the same product without incurring high upfront costs for a single large 3D printer.

Functional Printing

This approach uses 3D printed parts and components to increase the efficiency & productivity of industrial machinery. For example, a series of printed gears can replace heavy metal castings in a gearbox, increasing speed and reducing overall costs.

Risk Reduction

By allowing manufacturers to experiment with various designs, rapid prototyping ensures less costly mistakes at every level of product development. Besides, the reduced time taken to develop a prototype drastically decreases its cost of production. Thus, 3d printing makes it easier for manufacturers to bring down their final product price.

Wrapping Up

3D printing already has a firm foothold in industries and is likely to become a significant force driving Industry 4.0. Not only will additive manufacturing play a vital role in transforming the future of global business, but it will also offer numerous benefits to consumers. In the upcoming time, we will see more advanced additive manufacturing applications that will aid Industry 4.0.

This technology now makes it possible for manufacturers to design

3D printing offers greater precision over traditional processes